Services

Remote Group strives to be the first choice for all your Oil & Gas water needs.

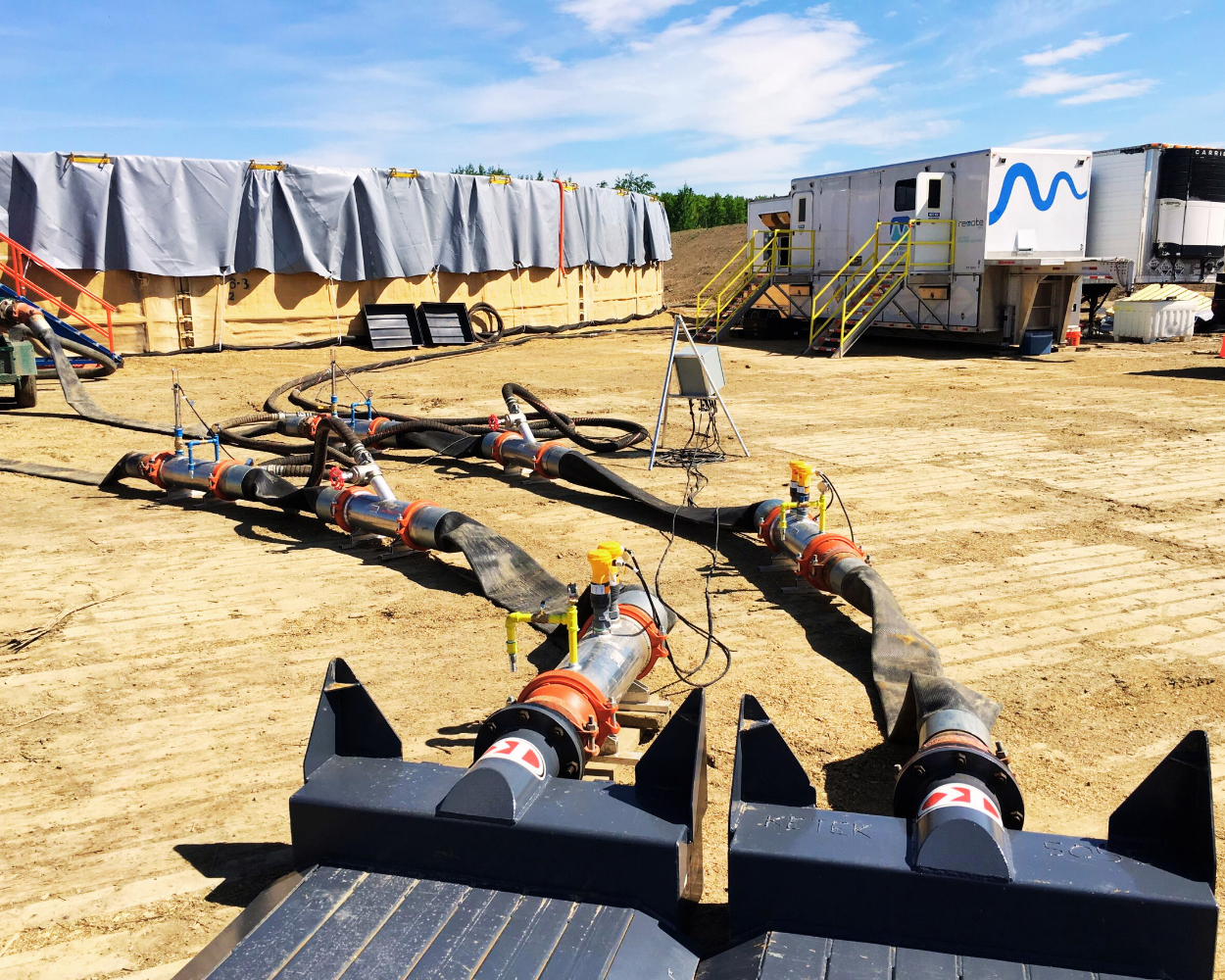

OILFIELD WATER SOLUTIONS

At Remote Group we’re constantly pushing the boundaries of water treatment within the Oil and Gas sector. Through our consultative engagement process, we can help you define and ultimately work through your water challenges, whether you’re trying to tackle microbial induced corrosion (MIC) in an upstream or midstream application, microbial induced souring, storage, recycling or reclamation, or completions water use in general, we can provide you with real-world, economically driven, science-based advice on how best to tackle your unique situation.

Contact us to learn more about:

- Flowback and Produced Water Recycling

- Continuous Oxidant or Biocide Injection for Midstream Applications

- Microbial Identification, Quantification and Activity Assessment

- ClO2 for “Frac-On-The-Fly” Applications

- Complete Pre & Post Treatment Water Analysis

- Preservative Biocides for Long-Term Protection

- Scale Inhibitors

- Solids Removal

- Additional Oxidation Services Including:

- H2S ‘Sweetening’

- Iron and Manganese Knock Back

- Preservative Biocide Demand Reduction

- Odor Removal

BIOCIDE SERVICES

Remote’s Biocide Services are second to none. We employ cutting edge techniques to determine minimum effective dose requirements, bacterial levels, and any water quality parameters that may need to be considered before charging into action.

Through our investigative approach we’ll uncover what the right products and processes are for your operation. We’ll help you ensure that your production goals will not be interrupted by unwanted biofilm, biological souring, or just overall lower than expected economic performance through faster than expected decline rates.

PRODUCED WATER RECYCLING

Solids Removal

Remote uses proven produced water treatment and solids removal processes that allow for cost-effective, clean, reusable frac fluid and eliminate the need for disposal. Through a specialized DAF and chemical delivery system, we can offer reliable and safe treatment at any volume while maintaining a small footprint. Remote’s DAF air system utilizes an industry-leading 30-micron bubble and cross-flow design to offer highly efficient flow rates with a minimal amount of energy. Our mobile units can treat 10,000 – 50,000 bbls per day, and we can help scale up our technology to meet the needs of temporary or permanent facilities that could handle from 100,000 to over 250,000 bbls a day. With the ability to handle up to 2500 mg/l TSS, the system can remove 99% of all solids and FOG found in produced water.

Sour Treatment

Remote offers a variety of options to treat sour fluid. H2S is one of the most dangerous compounds in the oilfield and is present in every shale play. With decades of combined experience, we can provide safe, reliable treatment options for tanks, pits, disposal sites, or sour fluid on the fly. Remote has treated over 15 million bbls of produced water in 2018 and saved hundreds of thousands of dollars in capital and downtime by handling each situation with the right solution, not just a product.

MICROBIAL IDENTIFICATION, QUANTIFICATION AND ACTIVITY ASSESSMENT

- Industry water quality and usability is directly impacted by its microbial composition and has profound impacts on well production, quality and longevity.

- Remote’s Microbial Assessment process utilizes robust microbial analytic tools designed to be incorporated with other water and production variables to create comprehensive, reliable and pragmatic solutions.

- Our microbial analytic systems are rooted in a cross-functional approach incorporating various traditional and contemporary techniques.

- We can combine culture-based “bottle-turn” techniques with enzyme-linked fluorometer analysis to provide fundamental microbial population and metabolic analysis.

- A more comprehensive 16S metagenomic analysis affords forensic-level identification of each bacteria and relative abundance within the ecosystem.

- Cumulatively, Remote’s approach facilitates water quality optimization in three critical ways. First, basic water-related bacterial quantity and composition is important to well health and a leading indicator of potential treatment needs. Second, we can enumerate bacterial populations in real-time thus allowing improved biocide selection and dosing optimized for well conditions and cost. Finally, forensic level microbial analysis can identify specific deleterious bacterially-related issues within a well (or group of wells) and subsequent targeted remediation solutions. Moreover, as microbial metabolites have profound health and safety impacts, proper and effective bacterial control in water is a critical component in Remote’s commitment to safely provide complete water solutions.

WATER QUALITY ANALYSES

Onsite Testing Of:

- Microbial Populations

- Chlorine – Total (tCl)

- Alkalinity – Total (as CaCO3 )

- Iron – Alternate (xFe)

- pH

- Sulfide

- Chloride • Sulfate

- Calcium as CaCO3

- Total Hardness (CaCO3 )

- Barium – Total

This system allows for rapid monitoring of potentially dangerous water constituents such as H2S, making it a critical part of our safety systems and our overall commitment to health and safety.

We’ve adopted several cutting edge technologies and subsequent data analysis tools to assess water chemistry. The system affords real-time analysis of water chemistries unique to variables such as water source, storage and ambient temperatures. These powerful techniques can be deployed in real-time at the wellsite to allow rapid and educated adjustments to optimize operations and overall oil recovery. Water systems can also be recreated and evaluated in the Remote R&D Laboratory to determine water impact on the quality of recovered hydrocarbon, eliminate potential interferences with services such as fracturing, and prevent structural malfunctions due to corrosion or scaling.

MOBILE SEPTIC WASTEWATER SOLUTIONS

Remote has been supplying packaged sewage treatment solutions to remote camps for a few industries since 2003, including oil & gas, construction, forestry, mining and small-scale municipal applications.At Remote we recommend using only the most robust systems for remote locations because any down time can cost your operations big time!

Remote provides its clients with the professionals and information they need for reliable, efficient wastewater treatment solutions. Our trained and experienced team will ensure your onsite wastewater treatment solution will perform under the harshest conditions when things just need to work!